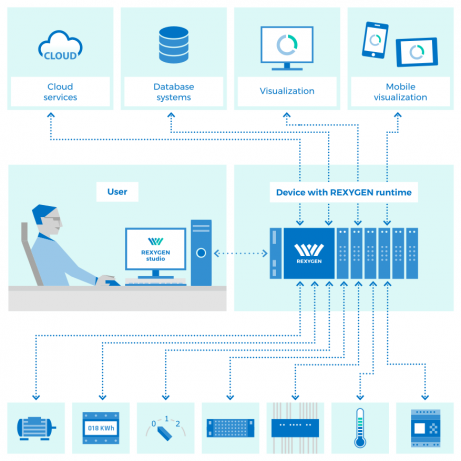

The family of REXYGEN software tools is extensively used in various fields of automation, process control and robotics.

Just like oxygen in nature, it is the essence of life for many devices, machines and technologies in the world of automation.

No more hand coding, no more trial-and-error

with third party libraries

Develop

- Develop on a standard PC or laptop

- No specialized cables or interfaces

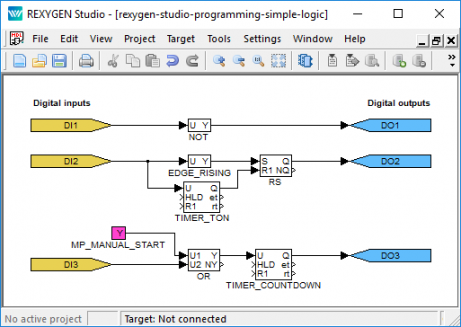

- Graphical programming based on function block diagrams

- Extensive library of industry-proven function blocks to build upon

- Split your project into individual tasks

- Use subsystems to create reusable components

- Design user interface for desktop, tablet and smartphone

Build and run

- Compile your project within seconds

- Compiler and all libraries are included out-of-the-box

- Run your algorithms on any of the supported hardware platforms

- No cloud-based solution, everything works locally.

- You have full control: your device, your algorithms, your data.

Test and observe

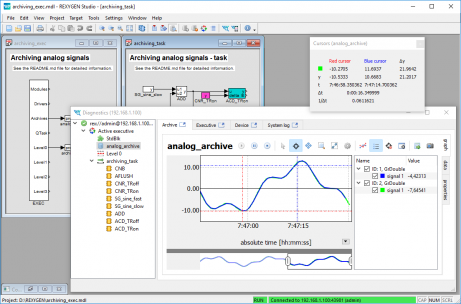

- Analyze overall control system performace

- Watch individual signals in real time

- Observe the information flowing through your algorithm

- Override and inject values to test the algorithms

- Adjust parameters and fine-tune the system on the fly

- Study system behavior using detailed time plots (live or archived)

PLC, PAC, DCS, IPC, (I)IoT node, Machine control unit, Data concentrator, Smart controller, you name it...

Modbus, OPC UA, OPC DA, MQTT and SQL through ODBC are natively supported communication protocols.

The development and deployment of a control system for production of powdered milk has been smooth and straightforward. All our needs in the PID control domain were covered by REXYGEN function blocks out of the box.

The improved efficiency and optimized throughput of the facility is kept by the PLCs ever since.

All three REXYGEN-enabled robotic manipulators on our production lines have proven to be extremely stable. After two years of operation, mostly in 24/7 mode, the error counter still sits at zero.

My hydroponics application requires only basic control algorithms but I like that REXYGEN with its libraries is capable of much more than I will utilize at the moment.

That along with the capability of creating the accompanying graphic user interface made REXYGEN the first choice for development of my hydroponics control system.

REXYGEN Studio: The engineer's tool

One development environment for all platforms

Graphical programming using the so-called function blocks provides a straightforward and convenient style of programming.

Your automation device can run a simple algorithm containing a few comparators and timers or you can turn it into a large-scale industrial control system.

Regardless of the complexity of your algorithm, you always have detailed diagnostics at your disposal. You can use either live or archived data to fine-tune your projects.